Principles of Operation

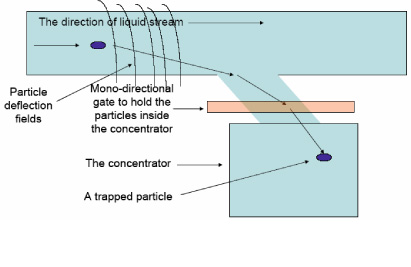

The Innosol emergency water unit eliminates suspended particles larger than 0.5 µm without using traditional filtration approach, by deflecting suspended solids into the so-called concentrator section of the Innosol device using electrostatic and magnetic fields, as well as other means available to modern physics. Usually (subject to concentration of suspended solids in source water), thousands of litres (or gallons) of raw water can be processed before the concentrator is filled. When full, the concentrator can be automatically emptied requiring no supervision, or when desired the concentrated suspended solids can be kept for advanced, statistically significant laboratory analysis of source water contaminants.

The Innosol suspended solids removal method often eliminates usage of consumables in the entire water purification process (only the optional activated-carbon filter requires periodic replacement, if it is used). Innosol operates with raw water turbidity as high as 15 000 NTU, which would clog a typical filter-based system in a few minutes.

Innosol-EWSD operations summary

The core Innosol emergency water unit (Innosol-EWSD) requires no chemicals or filters. Simply place the inlet pipe in raw water and receive suspended-solids-free water (above 0.5 micron) from the water outlet pipe. Because nothing is added during the water purification, the suspended solids in the Innosol’s concentrator contain only what was already present in the source-water, and can be safely returned to the environment with no adverse effects. In removing all solids larger than 0.5 µm, the Innosol emergency water unit removes bacteria, protozoa, parasites, cysts, and endospores. If viral contamination is a concern, a UV irradiation end-piece can be used. In cases where water is contaminated with dissolved chemicals, an activated carbon filter end-piece can be added. Such efficient removal of suspended solids substantially increases the efficiency of the UV disinfection, where used (preventing shading and encapsulation of microorganisms) and extends the life of charcoal filters. In most cases the charcoal filter and UV-disinfection end-pieces are not needed to produce clean water from Canadian lakes and rivers.

Technical Specifications

| Specification | Small Unit Innosol EWSD-S | Medium Unit Innosol EWSD-M | Large Unit Innosol EWSD-L |

|---|---|---|---|

| Service population | 10004 | 25004 | 20 0004 |

| Volume of Drinking Water Produced per Day | 5000 L (1320 gal) | 12500 L (3300 gal) | 100 000 L (26 400 gal) |

| Guaranteed removal for suspended solids larger than (equivalent diameter) | 0.5 µm. | ||

| Maximum water turbidity | 15 000 NTU | ||

| Weight | 12 kg (26 lb) | 20 kg (44 lb) | 70 kg (154 lb) |

| Power consumption | <100 W | <200W | <1500W |

| Power supply | 120 V (AC)1 / 12 V (DC) can be powered by car battery | ||

| Sample collection | Concentration of suspended solids from thousands of litres down to 1 L for analysis at an accredited microbiological laboratory2, 3 | ||

| Automation | Runs in fully automated mode. Requires no supervision | ||

| Maintenance | Self-cleaning, self calibrating. No consumable parts (optional charcoal filter and a UV-disinfection system) may be used where required. | ||

2 Volume of source-water from which particles are concentrated until the concentrate is disposed depends on turbidity of source-water.

3 1 L concentrate of suspended solids received from thousands of litres of source-water allows very high statistical significance, analysis validity, and convenience in usage at accredited microbiological lab facilities. Rinse-water used to evacuate the concentration chamber of adherent microbes may also be collected for analysis, where required.

4Based on 5 L (1.32 gal) per person per day; 2.5 L for drinking, 2.5 L for cooking and basic sanitation.

The North American Water Quality Association WQA selected the Innosol technology and instrumentation as one of the most important innovations. Search for Innosol here

"...Innovative Multi-Application Large Volume Contaminant Detector: Reduces Process Costs, Monitors Product Water Quality, and Enhances Consumer Safety...The new instrumentation platform, Innosol-PLF, allows in-situ (online) detection, sizing, counting, and advanced monitoring of a wide range of biological and inorganic suspended solids (and more) in thousands of gallons of water and other liquid media, allowing for a number of unique cost-saving applications in industrial, commercial, and municipal markets..."

See how Innosol instrumentation can benefit your facility

The value added summary breaks down the benefits of Innosol instrumentation stage by stage in water treatment processes so you can see what applies to your facility.

Free-of-charge on-site in-situ in-depth analysis of performance of all stages of water treatment processes and distribution.

Managers or engineers of Canadian and US Drinking water treatment facilities and water distribution systems are offered free-of-charge help to learn in depth performance of all water-treatment processes at their sites to identify ways of improving water quality, water safety, and economic efficiency of potable water production and distribution. Strict confidentiality guaranteed where requested.