Principles of Operation

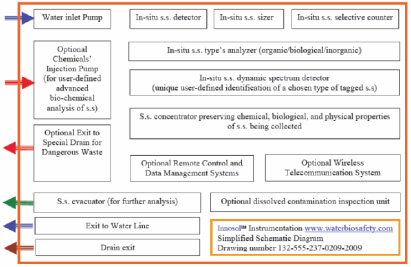

The Innosol instrumentation has a combination of modules that allow several water monitoring needs to be addressed as shown below. The Innosol instrumentation includes components that allow SS to be detected, sized, characterized by the type of, and counted as inorganic, organic, and biological.

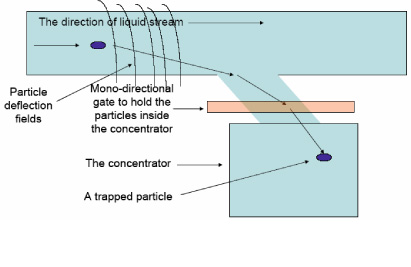

Furthermore, concentration of the SS from thousands of litres (or gallons) to a 1-L bottle (1/4 gal) for further lab analysis is achieved by replacing traditional filter-based methods of collecting suspended solids with the fundamentally new proprietary Innosol technology in order to preserve the physical, chemical, and biological properties of the SS. This is accomplished by using electrostatic and magnetic fields as well as other physical principles to trap SS. A dynamic spectrum analyzer in combination with an injection port for labeling compounds, where required, allows the Innosol to carry out highly customized advanced analysis of samples as well.

The instrumentation would produce visual, audio, and SCADA-compatible alarms as required by a customer, based on necessities of a specific water facility and/or authority. The in-situ water contamination data is available to a customer on-site and also remotely via Internet.

Technical Specifications

| Functions | |

|---|---|

| Particle Characterization | Sizing, counting, classifying (biological, organic, inorganic, user-defined types1) |

| Warning alarms | SCADA compatible alarms on detection of microbiological contamination or any user-defined change in measured parameters. |

| Sample collection | Concentration of suspended solids from thousands of litres down to 1 L for analysis at an accredited microbiological laboratory2, 3 |

| Automation | Runs in fully automated mode for several months. Requires no supervision |

| Remote data access | Data accessible at instrumentation console or remotely by internet |

2 Volume of Inlet water from which particles are concentrated depends on turbidity of inlet water. Inlet water of higher turbidity will fill the sample bottle more quickly.

3 1 L concentrate achieves very high statistical significance and convenience in usage at accredited microbiological testing facilities. Rinse water used to evacuate the concentration chamber of adherent microbes may also be collected for analysis.

| General | |

|---|---|

| Placement | in-situ1 |

| Volume of water analyzed per day | 14 000 L (3700 gal) |

| Power consumption | > 200 W |

| Power supply | 120 V (AC) / 12 V (DC) |

| Maximum measurement frequency | 3 min |

| Minimum water turbidity | 0.001 NTU |

| Maximum water turbidity | 50 NTU |

| Particle Sizing and Classification | |

|---|---|

| Number of user-defined particle size-range bins | 10 user defined ranges1, 2 |

| Minimum size of detectible particles | 1 µm |

| Max size detectible | 10 000 µm (1 cm) |

| Increment of size-range adjustment | 1 µm |

| Size classification error | 0.2 µm |

| Particle type classifications | Classifies as organic, inorganic, biological, or a user defined type based on spectral characteristics2, 3 |

2 A total of 10 distinct particle classifications can be made using a combinations of particle type and size. Additional capacity for classification bins can be obtained by special order.

3 Custom type classification is based on user-defined spectral characteristics. Users may use dyes to label specific particles. Size bins may overlap if desired.

The North American Water Quality Association WQA selected the Innosol technology and instrumentation as one of the most important innovations. Search for Innosol here

"...Innovative Multi-Application Large Volume Contaminant Detector: Reduces Process Costs, Monitors Product Water Quality, and Enhances Consumer Safety...The new instrumentation platform, Innosol-PLF, allows in-situ (online) detection, sizing, counting, and advanced monitoring of a wide range of biological and inorganic suspended solids (and more) in thousands of gallons of water and other liquid media, allowing for a number of unique cost-saving applications in industrial, commercial, and municipal markets..."

See how Innosol instrumentation can benefit your facility

The value added summary breaks down the benefits of Innosol instrumentation stage by stage in water treatment processes so you can see what applies to your facility.

Free-of-charge on-site in-situ in-depth analysis of performance of all stages of water treatment processes and distribution.

Managers or engineers of Canadian and US Drinking water treatment facilities and water distribution systems are offered free-of-charge help to learn in depth performance of all water-treatment processes at their sites to identify ways of improving water quality, water safety, and economic efficiency of potable water production and distribution. Strict confidentiality guaranteed where requested.